Rough Diamond Guide

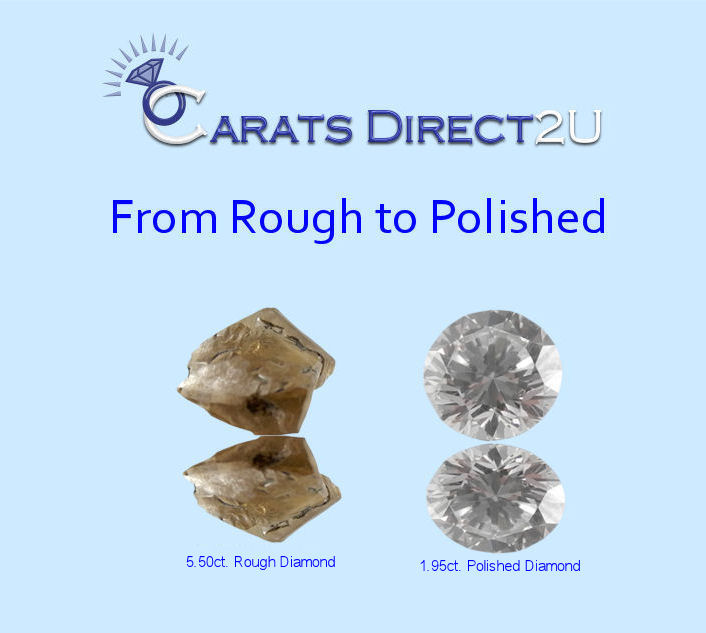

Rough Diamonds refer to diamonds which are still in their natural state after being removed from the belly of the earth. This is the stage before they are actually cut or polished in order to create the marvelous diamonds found in all of our unique jewelry.

To the uneducated eye, rough diamonds look more like a shard of glass that can be found anywhere. They are dull, oily looking and come in many colors. Rough diamonds are revered for their pure, untouched natural state. It is difficult for the layman to know or understand the value of a rough diamond.

The rough diamonds that eventually become the gem quality diamonds that we sell represent less than 20% of all diamonds that are mined. The other rough diamonds are sold as industrial diamonds.

Rough diamonds are sorted into groups according to their crystal qualities just like the categories of polished diamonds, such as shape, size, quality and color.

We have a large selection

of polished diamonds

Buying rough diamonds is an acquired skill developed over many years by those who purchase and sell rough diamonds. Once the rough diamonds are purchased, the end result is due to the creativity, expertise and skill of the manufacturer.

The eventual pricing of a diamond has a direct relation to the cost of the rough diamond. The end price to the consumer reflects the cost of the rough diamond, while only a small percentage of the end price to the consumer is attributed to the actual cutting and polishing of the diamond.

There Are Five Different Phases In Cutting A Rough Diamond

- Planning – This is by far the most important stage. This stage determines the size, clarity and shape of the diamond. If done incorrectly, even by a fraction of a millimeter, the results can be quite costly

- Cleaving/Sawing – Once the plan has been laid out, and agreed upon by the manufacturer and the cutters, the diamond is either cut as is, or alternatively cleaved or sawed. Sawing can be done with a diamond-coated rotary saw or a laser. This is the most dangerous step in the process. If one were to attempt to cleave, saw, or laser a diamond in the wrong position, the diamond could possibly shatter thus rendering it practically worthless.

- Bruiting – Bruiting or girdling is what contributes to the basic face-up outline of a round diamond in order to prepare it for polishing. While in this phase, the diamond which is being bruited is spun on a rotating lathe while at the same time another diamond is forced against it, gradually forming the rounded outline. Essentially, one diamond is used to shape the other.

- Polishing – This is the last and second most important step in the process, giving the diamond its finished proportions. The polishing of a diamond will determine how much brilliance and fire a diamond will eventually display. There are two steps involved in polishing a rough diamond:

- Blocking - The first 17-18 facets are polished, this outlines the shape of the diamond.

- Faceting – This step is often referred to as brilliandeering, and occurs is when the brilliandeerer “splits” the original 18 facets into the final 58 facets of the diamond.

- Final Inspection - This final stage involves thoroughly cleaning the diamond in acids, and examining the diamond to see whether it meets the quality standards of the manufacturer.

Polishing rough diamonds requires an incredible amount of patience, skill and consideration in order to transform the world's hardest material into a beautiful and valuable polished gem. The ultimate goal in polishing a diamond is to produce the best cut and the most carat weight possible while keeping production costs low, this insures that that the savings can be passed on to the customer. It is equally important to maximize the quality of the polished diamond.

CaratsDirect2Us’ Experience With Rough Diamonds

The CaratsDirect2U family has been manufacturing and cutting diamonds for over 60 years. Our rough buyers are also the diamond manufacturers. They travel the world to find the best rough suitable for diamond cutting and work closely with our diamond cutters to maximize the potential of the rough diamond while transforming them from their rough state into magnificent gems, polished diamonds.

When we purchase rough diamonds, our expert buyers can envision the final product and together with the expert cutters can maximize the cutting of the diamond so there is little wastage. When we complete the cutting process we are thus able to offer our customers the following shapes:

Our diamonds range in size from 0.5 Ct to 10 Carats.You are welcome to contact one of our professional jewelers at 1-800-557-7095 or [email protected] with any questions you may have.